COATINGS

Mirrors

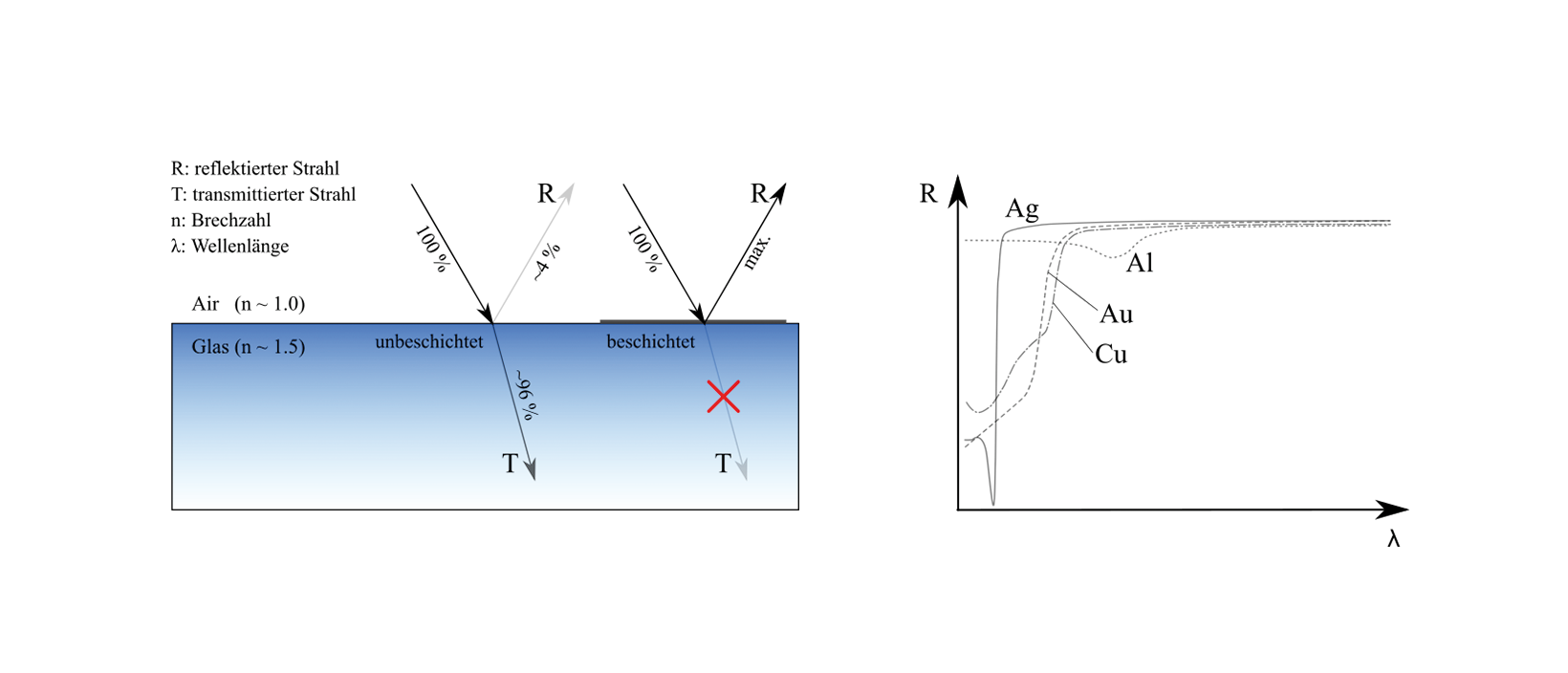

Metal-based

Metal-based mirror coatings contain at least one metal layer, which creates the main part of reflectivity. Materials such as aluminium, copper, silver or gold are usually embedded in dielectrics to protect them from environmental influences and to specifically optimise the optical properties.

Compared to purely dielectric mirror coatings, metal-based mirror coatings have a significantly lower dependence of the reflectivity of wavelength, incidence angle and polarization, as well as a smaller overall layer thickness.

Opcos’ metal-based mirror coatings are characterized by high reflectivity and good resistance to external influences such as harsh climatic conditions and laser strength.

Depending on the design and selection of materials, this mirror type can also be used for wavelengths above 5 µm

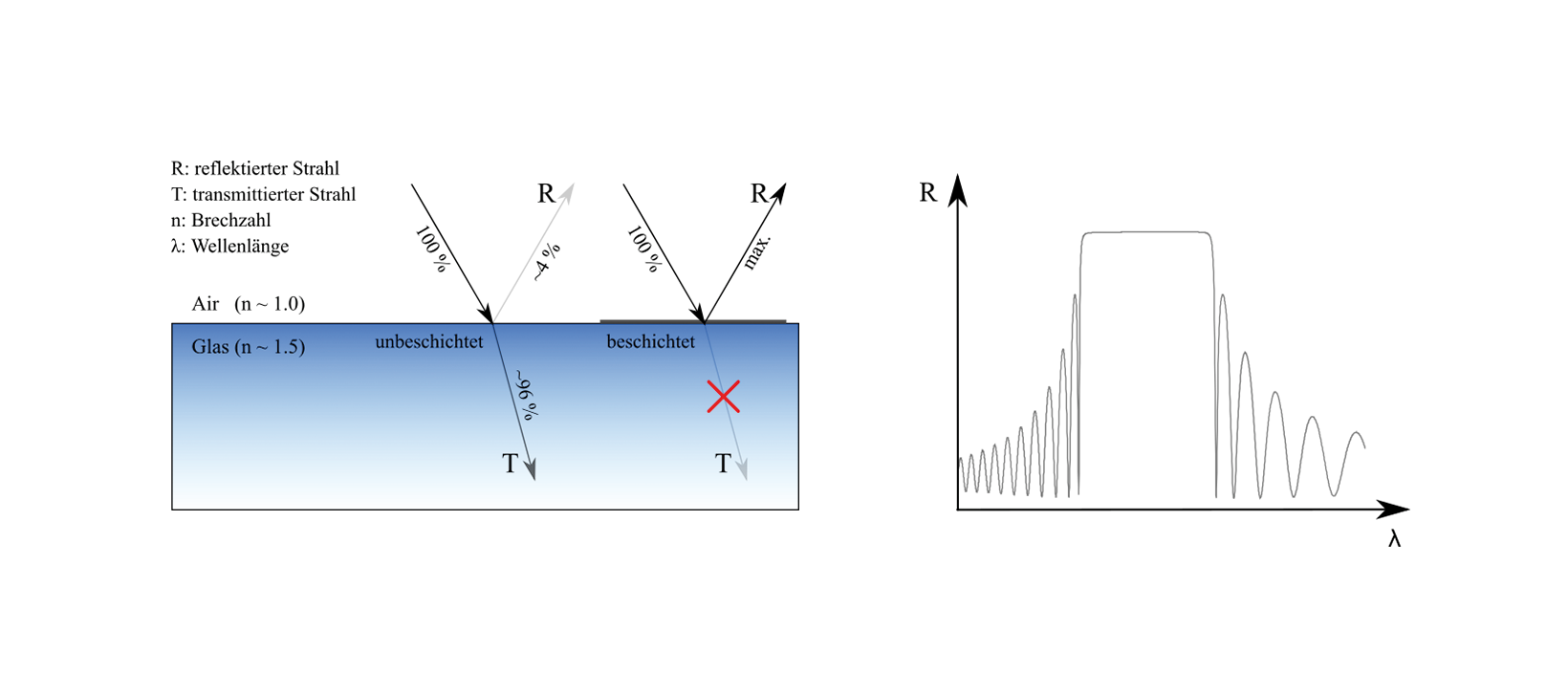

Purely dielectric

Purely dielectric mirrors are used, when very high reflectivity is required in specific wavelength and angle of incidence ranges, for example in applications with high-power lasers. This is achieved with multilayer packages made of dielectric materials of different refractive indexes.

Such coatings are usually more cost-intensive than metallic mirrors, since both the number of individual layers and the overall thickness of these layer packages are significantly larger.

Reflection levels >99.9 % can be achieved for discrete wavelengths and angles of incidence with very high environmental stability.