COATINGS

Specials

Homogeneous layer thicknesses on strongly curved surfaces

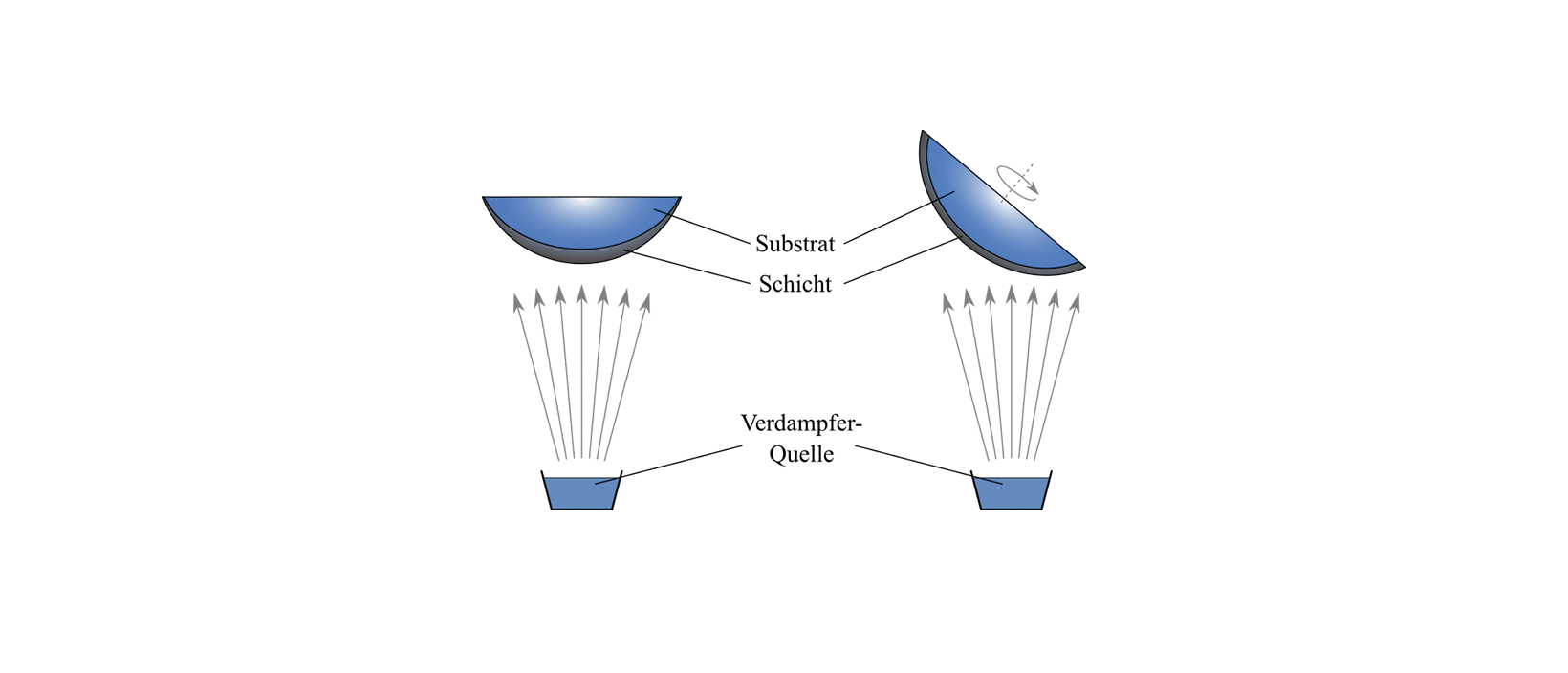

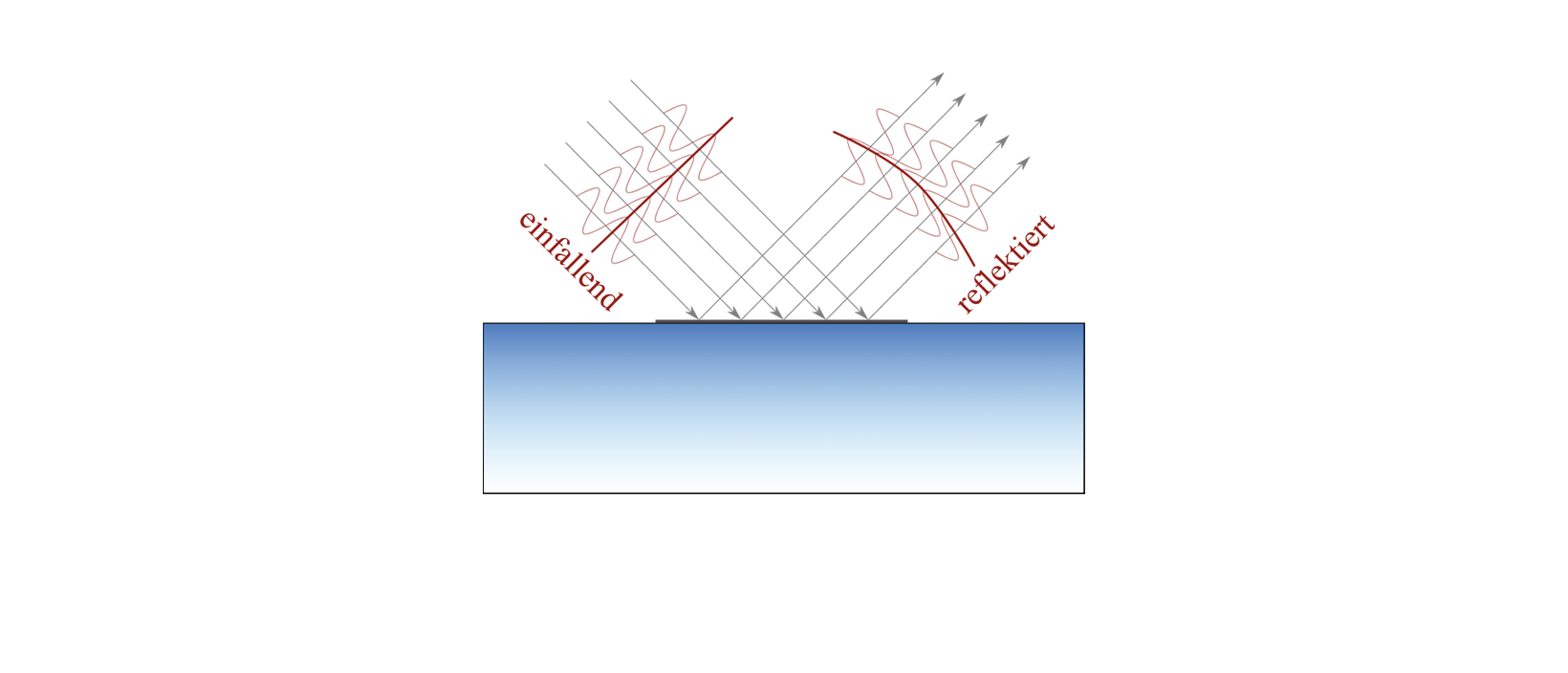

The coating layer in PVD processes does not grow up with homogeneous layer thickness on substrate surfaces, which is due to the nature of the process with directed particle beam, therefore the layer thickness varies laterally. The optical and mechanical properties of the resulting coating follow the resulting layer thickness gradient.

These effects can be counteracted in many cases by targeted adaptation of the layer design, but especially on strongly curved surfaces, those effects may lead to insufficient results.

To minimize the layer thickness gradient and the associated performance effects, substrates with rotationally symmetrical surface shapes can be put into self-rotation by means of planetary gears.

Opcos AG developed an own planetary system and in its application very flexible planetary gearbox to be able to serve a wide range of products. In addition, the lateral layer thickness gradient for a given surface can be estimated and compensated by means of in-house simulation software developed in advance, which significantly reduces the expenditure for this purpose optimisation test.

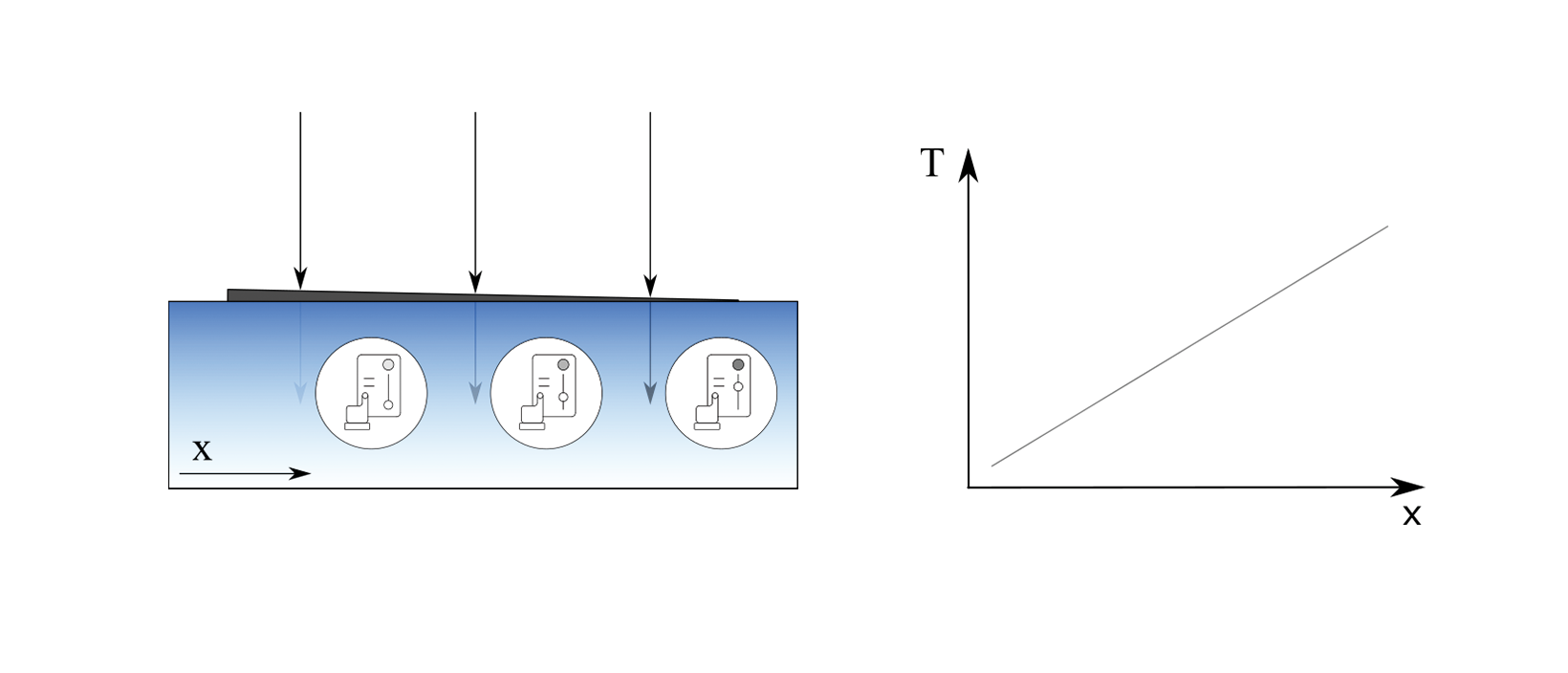

Gradient filter

When a lateral variation of the optical properties of a surface is expressly desired, so-called gradient filters are used, in which the function is adjusted by specifically adapting the layer system to different locations of the coated surface.

Rimless coatings

Usually, substrates for positioning within the coating system are typically placed in a product-specific holder, so that a part of the surface to be coated in the holder and is therefore not or only partially coated in these places.

Opcos' innovative mounting concept is retained for many substrate geometries, such as lenses and rod lenses > 2 mm, without support points, which allows a full-surface homogeneous coating of the surfaces. In addition, the cleaning and coating of substrates in these mounts is also tested at high process temperatures, which means that this holder concept has no limitations for our large portfolio of coatings.

TCO

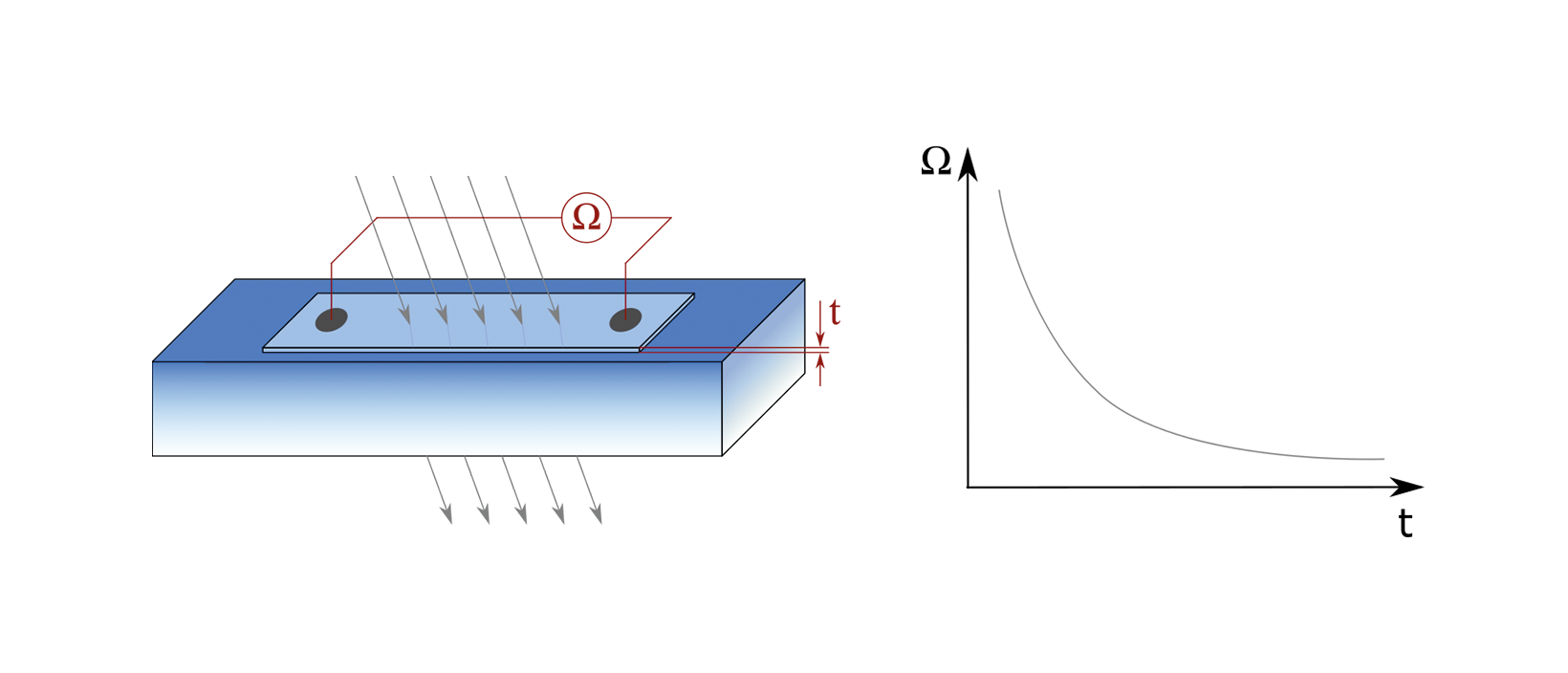

Transparent conductive coatings are used in the solar, electronics, military, and display technology. For example, TCO coatings can ensure that a surface may be electrically heated, protects against static charge, or shields electromagnetic radiation and has specific optical properties.

The electrical surface resistance is a function of layer thickness and can be combined with other types of optical coatings available by Opcos.

Wavefront control (RWE, TWE)

Sophisticated optical systems often have high demands on the preservation or targeted modification of wavefronts on incident light rays when passing through optical surfaces, elements, or the overall optical system.

At Opcos AG, those requirements of the coatings for your optical systems are already considered during the coating design.

Polarization and phase control

If light hits an optical surface with a large angle of incidence, polarization effects occur. In many applications, it is important what phase relationship in light waves of different polarization directions are to each other, or what their amplitude ratio is. Such effects can be reduced or used in a targeted manner thanks to a high level of process control in the coating procedures established at Opcos AG.

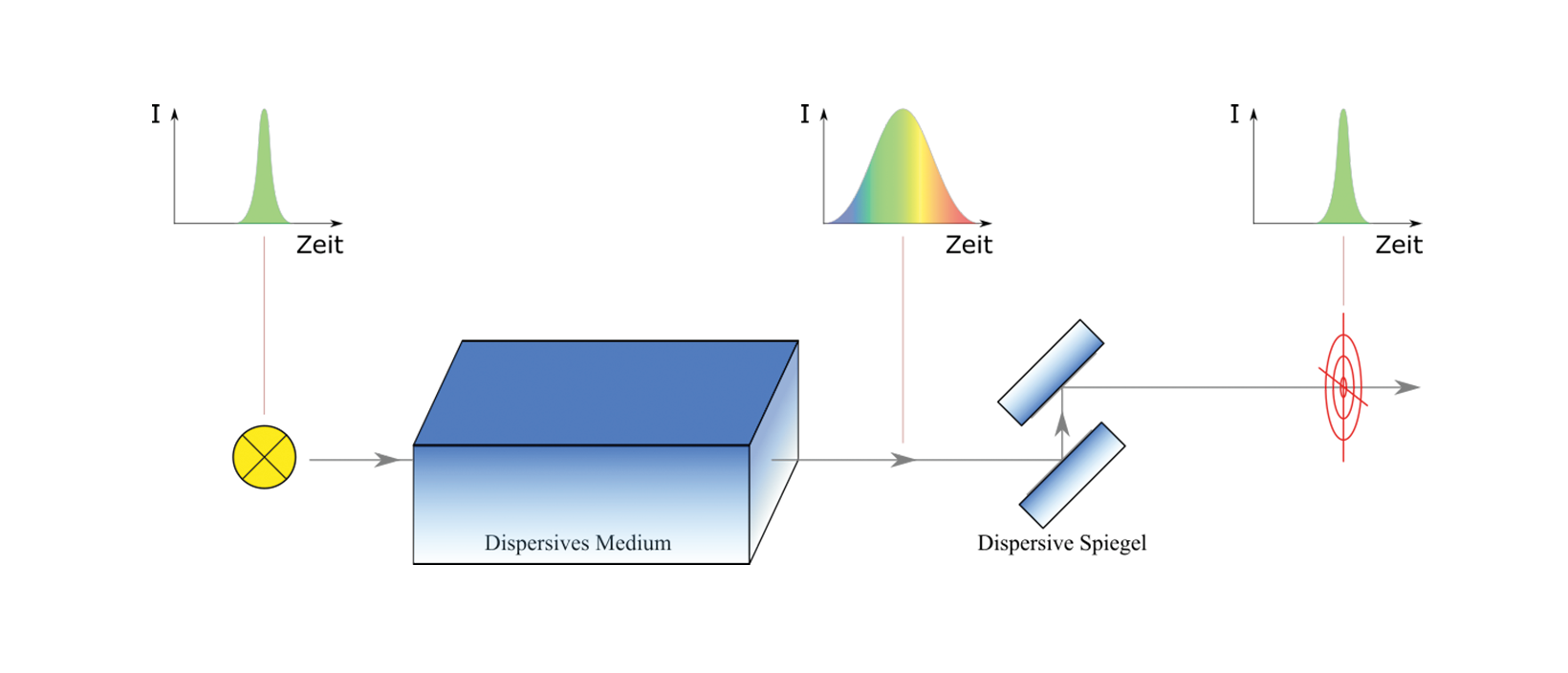

A tailor-made course of phase shift over a spectral band can also be realized, as is used, for example, during the (re-)compression of ultrashort laser pulses in order to counteract temporal pulse spreading after passing through a dispersive optical medium (dispersive mirror).